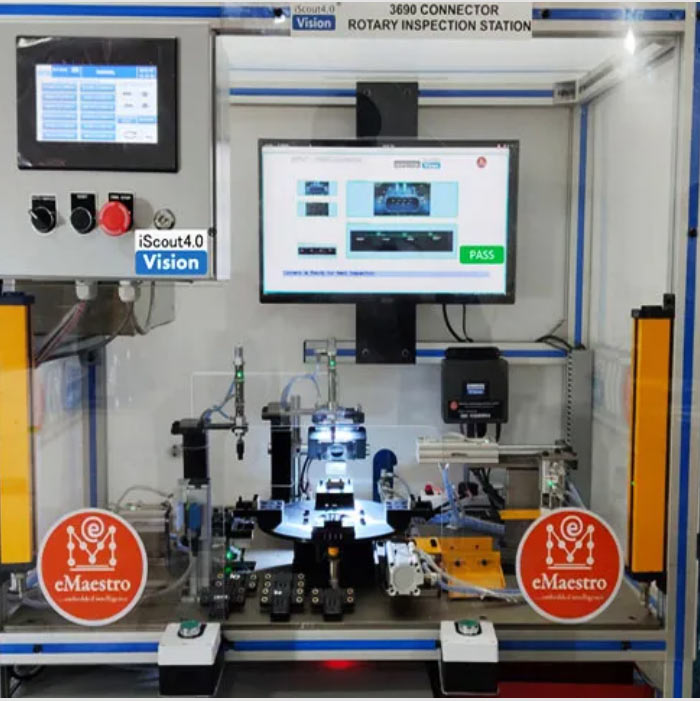

AI Based Visual Inspection System Manufacturers in India – eMaestro Technologies

eMaestro Technologies is Premier AI-Based Visual Inspection System Manufacturers in India, Suppliers and Exporters in India. Our systems are fully bespoke AI-based inspection systems capable of detecting any minor surface flaws, pattern changes, dimensional errors, or anomalies that a conventional machine vision system could not. Our AI models are self-learning and self-improving, which makes them suitable in complex production environments that have high speeds and high variations.

What is an AI-Based Visual Inspection System?

An AI-Based Visual Inspection System is a high-end quality control system that involves artificial intelligence (AI), machine learning (ML), and computer vision to perform automatic product inspection, defect detection and correct manufacturing verification. In contrast to the conventional attitude where vision systems use fixed rules to detect defects, variations, and patterns, AI-based inspection systems adapt to real-world examples, becoming able to detect complex defects, variations, and patterns with human-like intelligence at a significantly greater speed and accuracy.

Types of AI-Based visual Inspection systems

We are AI-Based visual Inspection systems Manufacturers in India and following are various types of AI-Based visual Inspection systems we offer.

- Fixed: AI Inspection System for Manufacturing Fixed on a line of production and inspected continuously in large volumes.

- Portable: Can be transferred to various points, can be used when the volume of inspection is low or when the inspection requirements are varied.

- 2D: Artificial Intelligence Visual Inspection Checks flat areas, such as scratches, frequently in electronic production.

- 3D: Produces a complex shape in 3D detail to identify defects such as dents or misfits, perfect in a motorcar or airplane.

- Single vs. Multi-View:

- Single-View: Automated Visual Inspection Powered By AI Single-angle images, which are adequate when using simple parts.

- Multi-View: AI-Enabled Visual Inspection involves the use of a large number of cameras of various angles so that a more detailed view is obtained, which is necessary when the part being viewed is complicated.

Fixed vs. Portable:

2D vs. 3D:

Technical Specifications of AI-based Visual Inspection System

As AI-based Visual Inspection System Suppliers in India, we have added below a table of Technical Specifications for this System.

| Specifications | Details |

|---|---|

| System Type | AI-Based Visual Inspection System |

| Inspection Method | Machine Vision with AI & Deep Learning Algorithms |

| Camera Type | High-Resolution Industrial Cameras (2MP – 20MP or customizable) |

| Lighting | LED, Structured, or Diffused Lighting Options |

| Processing Unit | High-Performance CPU/GPU or Edge AI Processors |

| Defect Detection | Surface defects, misalignment, dimensional deviations, missing components |

| Accuracy | Up to Micron-Level Precision |

| Speed | Real-Time Inspection on High-Speed Production Lines |

| Integration | Compatible with Automation, Robotics, and PLC Systems |

| Software | AI-Powered Image Analysis, Reporting, and Data Logging |

Benefits of AI-Based Visual Inspection System

We are AI-Based Visual Inspection System Suppliers in India and below are some of the key Benefits of this System.

- High Quality and reliability. Artificial intelligence-based inspection systems can also detect the smallest possible defects and anomalies with high accuracy and provide uniform quality of each product batch.

- Reduced Human Error AI Based Visual Inspection System With automation of the visual inspection, there is no human error, and quality control is more reliable and repeatable.

- Real-Time Inspection AI Based Visual Inspection System in India systems scan products immediately on production lines, and the defects are identified immediately, so defective products are not sent to the market.

- Adaptable and Self-Learning Machine learning algorithms constantly learn and thus would be able to deal with new product designs and complicated defect patterns without having to be reprogrammed.

Applications of an AI-Based Visual Inspection System

As AI-Based Visual Inspection System Exporters in India, our Systems are widely used in following key areas.

- Electronics and Semiconductor Industry. AI Visual Inspection System finds any soldering defect that can be found, displaced components, scratches on the surface, and missing or damaged components on the PCBs and semiconductors to produce quality electronics.

- Automotive Industry AI-Based Visual Quality Inspection systems check parts, assemblies, welds, paint finishes, and surface defects of vehicles in real time to enhance the quality and safety of vehicles and minimize the number of mistakes made in the manual inspection process.

- Healthcare and Pharmaceutical Industry. The inspection of AI makes sure that the labeling is done correctly, the integrity of packaging is maintained, the inspection of blister packs is performed, and the contaminants are detected to ensure that all the regulations are followed strictly.

- Food and Beverage Industry AI-Powered Visual Inspection Applied in the detection of packaging defects, foreign objects, mislabeling, and the variation in product appearance, in ensuring food safety and quality.

Why choose us?

- Cutting-Edge AI Technology We use the recent advancements in artificial intelligence, machine learning, and computer vision to provide the best and most reliable visual inspection solutions that fit the current manufacturing requirements.

- Industry-Specific Customization Our AI systems can be fully customized to comply with the inspection needs of electronics, automotive, pharmaceuticals, food and beverage, textile, among other industries with unique requirements.

- Outstanding Precision and uniformity. Our solutions do not miss any defects and irregularities, even on a micron level, and provide uniformity in the quality of products on each batch.

eMaestro Technologies is Superb AI-Based Visual Inspection System Manufacturers in India, Suppliers and Exporters in India. Visual Inspection Systems is an AI-based technology provided by eMaestro Technologies that has redefined how industries operate as far as quality and efficiency are concerned. Our systems will provide the highest accuracy, reliability, and speed in detecting defects and controlling the processes through the integration of artificial intelligence, machine learning, and cutting-edge imaging technology.

FAQ

Automation reduces labor costs, minimizes material waste, prevents defective products from reaching the market, and lowers expenses related to rework or recalls.

Yes. Modern AI inspection systems are built to perform reliably under vibrations, dust, moisture, and temperature variations common in industrial settings.

Yes. AI visual inspection systems capture inspection data, images, and logs that can be used for product traceability, compliance reporting, and process optimization.