Dimensional Check Vision System Manufacturers in India – eMaestro Technologies

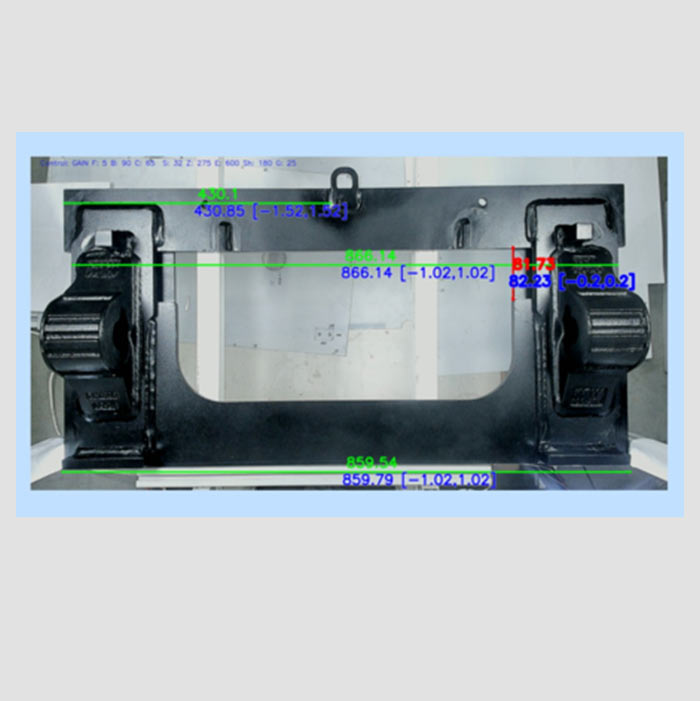

The eMaestro Technologies is Topmost Dimensional Check Vision System Manufacturers in India, Suppliers and Exporters in India .Our solutions combine high-resolution cameras, intelligent image processing and AI-driven algorithmic to measure automatically and ensure the dimensions of components and assemblies with high precision. Through real-time inspections, our system will be able to identify deviations, dimensional inconsistencies and assembly mistakes at an early stage of production, and thus minimize the rework rate and ensure that the products are manufactured under the strict industry requirements.

What is the Dimensional Check Vision System?

A Dimensional Check Vision System is an automatic inspection system that measures and checks physical dimensions of components, parts or assemblies with a high level of accuracy. The system is capable of real-time monitoring made by high-resolution cameras, high-end image processing, and AI-driven algorithms to identify deviations in length, width, height, angles, diameters, and 3D Machine Vision Systems decisive measures.

Types of Dimensional Check Vision System

We are Dimensional Check Vision System Manufacturers in India and following are various types of Dimensional Check Vision System we offer.

- Function: Automatic Cable Dimensional Measurement System Measure linear dimensions, e.g., height or distance between two points.

- Application: The best to use in cases involving simple tasks such as checking the height of an object on a conveyor belt.

- Function: Find two dimensions of a flat image, i.e., length and width. They apply cameras, light, and algorithms to scan objects based on their surface properties.

- Application: Common Use: 2D Measurement Inspection used to inspect flat parts such as printed circuit boards, labels or in checking the dimensions of parts on a 2D plane.

1D vision systems

2D vision systems

Technical Specifications of Dimensional Check Vision System

As Dimensional Check Vision System Suppliers in India, we have added below a table of Technical Specifications for this System.

| Component | Specification / Details |

|---|---|

| Camera / Image Sensor | Industrial-grade CMOS sensor (global shutter preferred for moving parts) |

| Resolution | Typically 5–20 MP, depending on field-of-view and required sub-pixel accuracy |

| Frame Rate | ~ 30–120 fps for most inspection lines; higher frame rates if needed for fast-moving parts |

| Exposure / Shutter | Configurable exposure; global shutter minimizes motion blur during movement |

| Lens / Optics | Telecentric or precision measurement lenses; focal length typically 12 mm, 16 mm, 25 mm, etc. - Low distortion lenses for accurate measurement |

| Optical Resolution | Specified in line-pairs/mm (lp/mm), chosen based on the smallest feature to be measured |

| Illumination / Lighting | Backlights, diffuse illumination, or structured lighting for high contrast/edge detection depending on part geometry |

Benefits of Dimensional Check Vision System

We are Dimensional Check Vision System Suppliers in India and below are some of the key Benefits of this System.

- High Accuracy: Dimensions are measured with an accuracy of a micrometer, which guarantees high quality.

- Consistency Quality: Dimensional Check Vision System in India gives the same inspection results, which do not involve variability in manual measurement.

- Real Time Inspection: Dimensional Check Vision System is the measure that identifies the dimensional deviation in real-time and enables corrective measures to be taken immediately.

- Scrap and Rework: Scrap and Rework are the errors that are discovered at an early stage, which minimize material waste and delays during production.

Applications of Dimensional Check Vision System

As Dimensional Check Vision System Exporters in India, our Systems are widely used in following key areas.

- Assembly Verification: Vision Systems for Dimensional Metrology making sure that the components are properly assembled and aligned, and spaced.

- Surface & Edge Inspection: 7 Dimensional Inspection System identification of an irregularity in edges or corners, or key surfaces.

- Gap and Clearance Checks: Machine Vision Dimension Measurement System Assemblies, Gaps and tolerances and clearance of assemblies.

- Angle and Alignment Checking: Vision system for Dimensional Check Checking of angles, inclinations and orientation of parts.

Why choose us?

- Specialization in Precision Inspection: Specializes in the design of vision systems to provide checks of the dimensional accuracy.

- Custom Solutions: Systems are designed to meet specific requirements of components, production lines and measurements.

- Large Accuracy and Consistency: Vision AI can guarantee accurate measurement and the ability to produce consistent results.

The eMaestro Technologies is Supreme Dimensional Check Vision System Manufacturers in India, Suppliers and Exporters in India. We are Dimensional Check Vision System offers a state-of-the-art technology to guarantee the accuracy, dependability and uniformity of measurements of all parts and machines. The system uses combining high resolution images with textual analysis and real-time inspection, dimensional verification, gap measure, angle checks and assembly validation are automated with a high degree of accuracy.

FAQ

The system is engineered for seamless integration with minimal disruption to ongoing manufacturing processes.

Improved accuracy, consistent quality, faster inspection, reduced scrap and rework, real-time monitoring, and compliance with industry standards.

We offer customized, reliable, and scalable vision solutions with expert support, advanced technology, and proven results for dimensional inspection.